I ran the flush trim bit around the backs and finalized my plan for the baffles. The Quarters will have removable upper and lower front baffles held in place by threaded inserts and joint connector bolts. The upper baffle with the driver rebates will be 3/4 inch Baltic Birch and the face painted with leftover paint from an accent color in the living room. The lower baffle will also be 3/4 inch Baltic Birch with the 5/8 inch acacia butcher block glued on top. The thicker lower baffle well help support the magnetic grilles.

That is some good looking quality plywood - hope you can recover from the mistake on the tweeter - how about using your existing measurements/CNC design to cut an inlay to fill the hole then recut a new one?

Might look fancy . . .

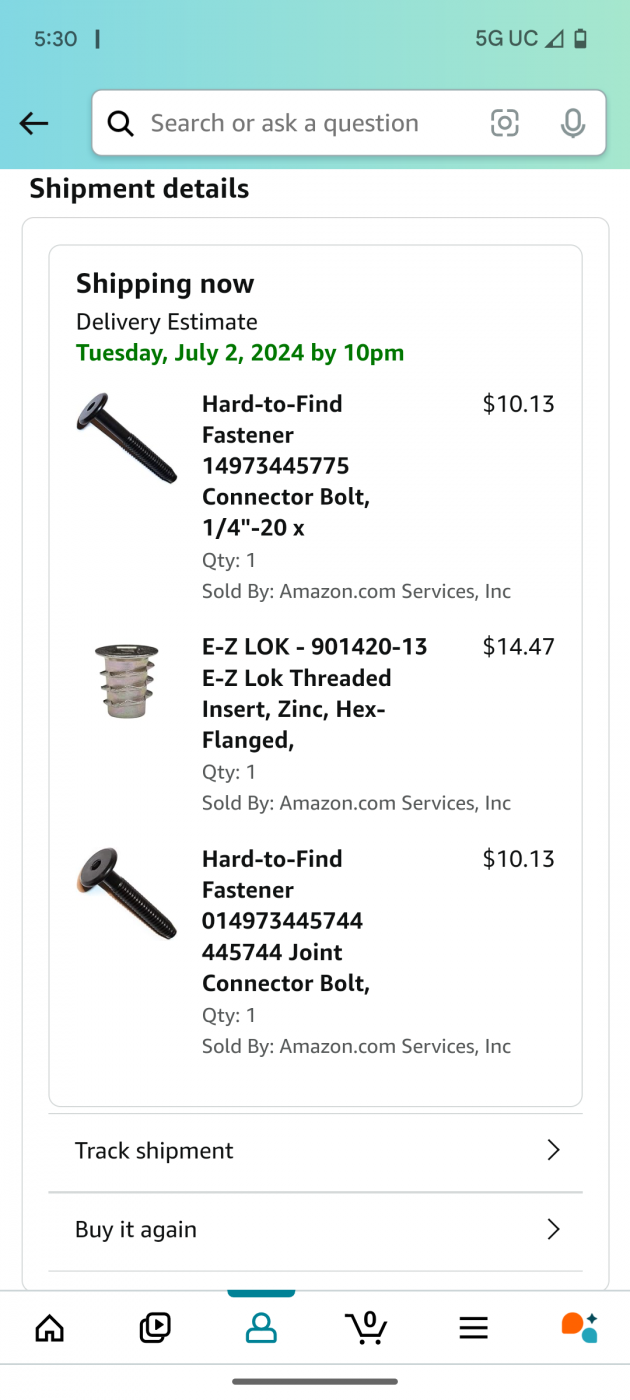

Steve, I flush trimmed the baffles but didn't mount them in preparation for the CNC driver rebates. The CNC will also locate the mounting holes. What you see there is my first test. I test fit all the drivers and updated my CAD and I'm now cutting a second test.

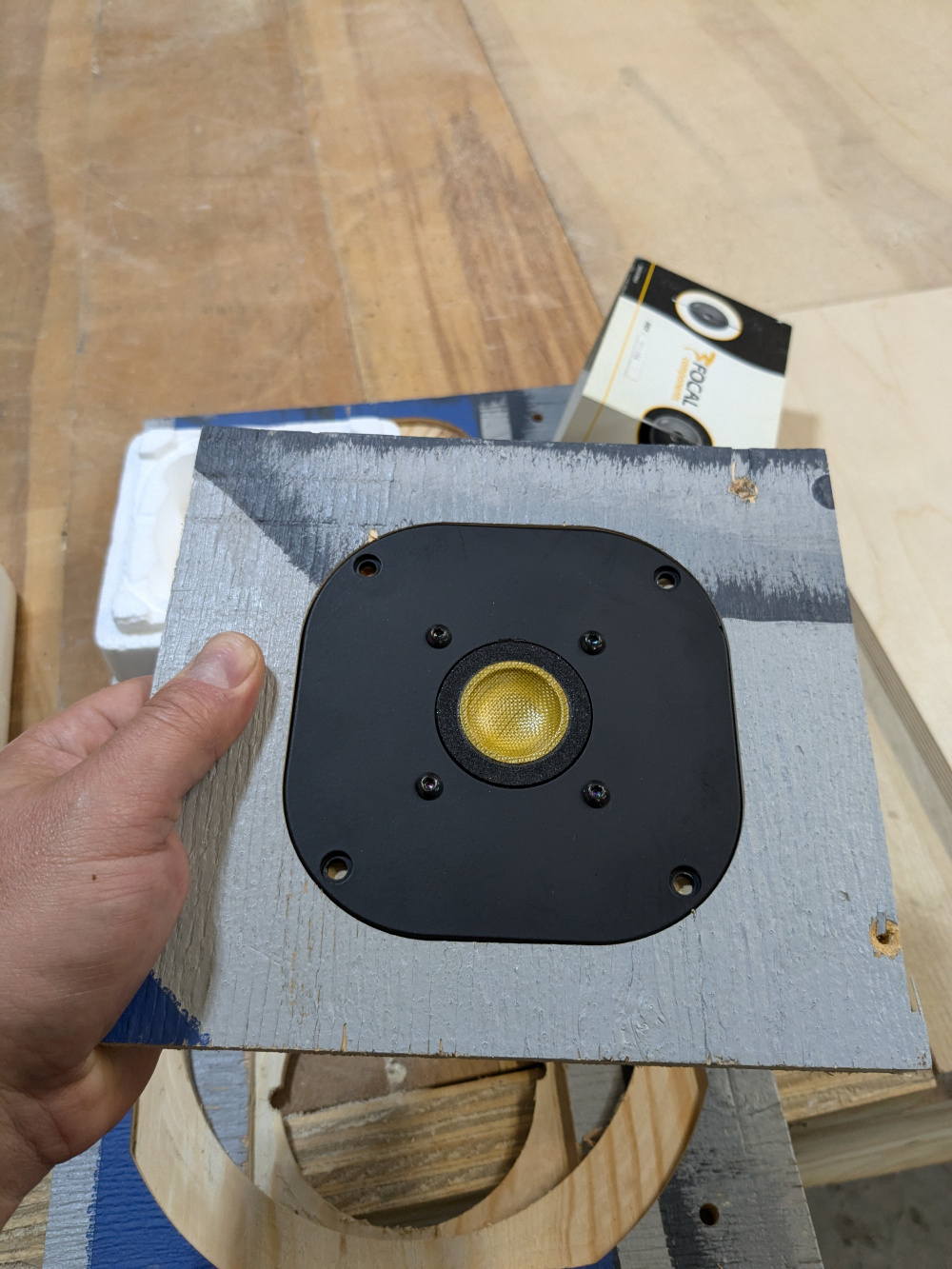

Well, the tweeter recess is the correct shape, but I need to add a half millimeter vertically and horizontally for the faceplate as it doesn't want to fit in. The mid recess fits well but the cutout needs another millimeter as well. Woofer fits well.

Thus far, that is really the only Focal tweeter before going completely OEM that I liked. It was not easy to use, and got a bad reputation, but it sounded better than all the others to me.

I remember the day I went to Fishers, Indiana to Phil Bamberg's place back in 2002. My cousin was along for the ride and Jeff attended as well. This was also the first outing for Jim Salk with his then recently started company, and he had 2 versions of his Veracity bookshelves present. Jeff Yourison i think came down too. A couple guys that build together from Richmond, IN (Russ(?) and Mike Leventhal) came with a homebrew TL MTM, composed of these Focal tweeters and a mismatched set of midbasses. Each side had a 18W/8535 and a 18W/8545 (and not the newer K version) flanking that Kevlar. Jeff stated he liked Focal drivers, but wasn't a fan of their tweeters as yet. One of the Richmond guys replied with certainty that he would like these. There were maybe 7 pairs present not including Phil's "BESL System 5" active setup (Peerless xls10/12PR, W18/Millennium MTM tops with DC coupled Threshold amps for the tops, Aragon for the lows, and a DCX running the show sent from a Premier Pre and Premier upside down cd transport.) I learned a lot that day about sound preferences, how drivers sound different, absolute phase, sound over looks importance, and room acoustics. This was my 3rd outing where I was able to hear other('s) speakers, first being Jeff's place, second being Dayton DIY 2002. I was 24 at the time. This was the only time Jeff got to hear the first major monkey coffin build I did that he assisted in the xover, and said I did okay on the build. Knowing what I know now, they really could have been a lot better. He was being really nice.

Good memories....

So I realized the other piece of 3/4 birch plywood I was going to use for the lower baffles is of lesser quality and has voids which is troublesome because all you were going to see were the plies once the acacia was glued on. I have some half inch birch plywood that would work, but just remember that I will now have some scrap rift & quarter sawn white oak flooring I could use. This will be the flooring that the speakers are sitting on in the new house. Suggestions?

Removable baffles without stiffening on the back of them will tend to flex at 3/4" thicknesses. I recommend 2 more bolts in the middle to keep them firmly mounted w/o flex.

Thanks for the feedback. I have a plan to use 3/4 birch scraps to fill the need and achieve the aesthetic. Ben, I'll look into adding another pair of bolts while maintaining symmetry.

You are welcome! My Fenrir had 1.25" thick MDF baffles, and I should have used 2 more bolts for best flatness. Therefore, I did on the Versabox related builds, and all have 6 mounting bolts.

Good question Ani. Since the woofer and tweeter are no longer obtainable and I have a four and a half year old, grills are a must. I didn't show the grill in my cad files, but I plan on CNCing a grill with magnets where the bolts are. The magnets may not be strong enough to hold the grill up, but should hold it against the baffle and the step will hold it up. The grill will be flush with the lower acacia baffle and hopefully provide a clean aesthetic. Another reason for the ply backer is to prevent the acacia from splitting when tightened down.

Comments

Is that a passive or port.

https://www.jfcomponents.com/

Went with the OG precision port. Easy to take out and change if needed.

I ran the flush trim bit around the backs and finalized my plan for the baffles. The Quarters will have removable upper and lower front baffles held in place by threaded inserts and joint connector bolts. The upper baffle with the driver rebates will be 3/4 inch Baltic Birch and the face painted with leftover paint from an accent color in the living room. The lower baffle will also be 3/4 inch Baltic Birch with the 5/8 inch acacia butcher block glued on top. The thicker lower baffle well help support the magnetic grilles.

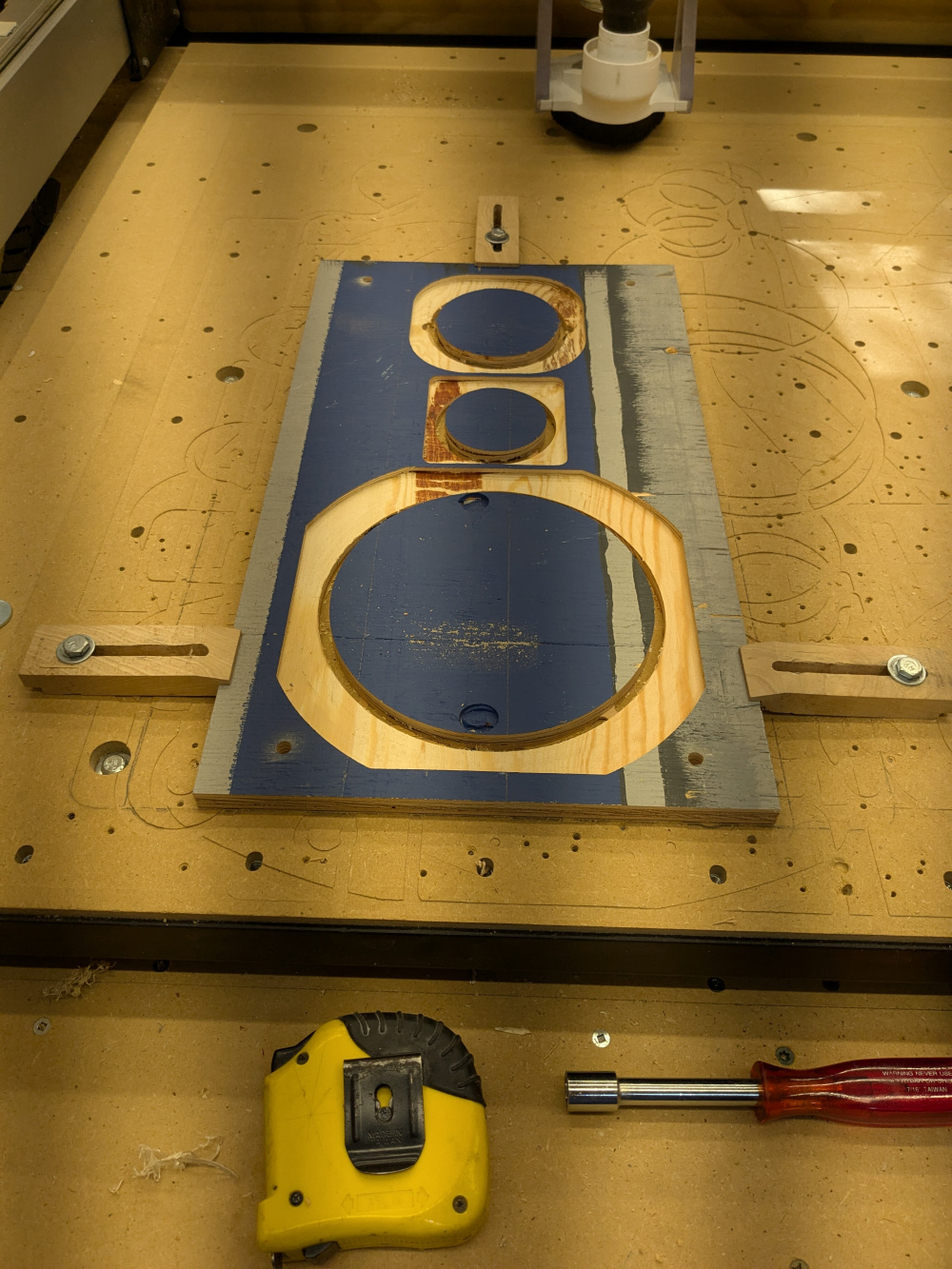

Added the threaded insert mounts

I cut the top baffles and flush trimmed them. Then I test cut the driver rebates on the CNC. Boy were my measurements off for the tweeter.

That is some good looking quality plywood - hope you can recover from the mistake on the tweeter - how about using your existing measurements/CNC design to cut an inlay to fill the hole then recut a new one?

Might look fancy . . .

Steve, I flush trimmed the baffles but didn't mount them in preparation for the CNC driver rebates. The CNC will also locate the mounting holes. What you see there is my first test. I test fit all the drivers and updated my CAD and I'm now cutting a second test.

Well, the tweeter recess is the correct shape, but I need to add a half millimeter vertically and horizontally for the faceplate as it doesn't want to fit in. The mid recess fits well but the cutout needs another millimeter as well. Woofer fits well.

Thus far, that is really the only Focal tweeter before going completely OEM that I liked. It was not easy to use, and got a bad reputation, but it sounded better than all the others to me.

I remember the day I went to Fishers, Indiana to Phil Bamberg's place back in 2002. My cousin was along for the ride and Jeff attended as well. This was also the first outing for Jim Salk with his then recently started company, and he had 2 versions of his Veracity bookshelves present. Jeff Yourison i think came down too. A couple guys that build together from Richmond, IN (Russ(?) and Mike Leventhal) came with a homebrew TL MTM, composed of these Focal tweeters and a mismatched set of midbasses. Each side had a 18W/8535 and a 18W/8545 (and not the newer K version) flanking that Kevlar. Jeff stated he liked Focal drivers, but wasn't a fan of their tweeters as yet. One of the Richmond guys replied with certainty that he would like these. There were maybe 7 pairs present not including Phil's "BESL System 5" active setup (Peerless xls10/12PR, W18/Millennium MTM tops with DC coupled Threshold amps for the tops, Aragon for the lows, and a DCX running the show sent from a Premier Pre and Premier upside down cd transport.) I learned a lot that day about sound preferences, how drivers sound different, absolute phase, sound over looks importance, and room acoustics. This was my 3rd outing where I was able to hear other('s) speakers, first being Jeff's place, second being Dayton DIY 2002. I was 24 at the time. This was the only time Jeff got to hear the first major monkey coffin build I did that he assisted in the xover, and said I did okay on the build. Knowing what I know now, they really could have been a lot better. He was being really nice.

Good memories....

InDIYana Event Website

There we go! On to cutting the baffles from baltic birch.

First one done.

Installed baffle hardware and did a test fit.

Now to make the lower baffles.

So I realized the other piece of 3/4 birch plywood I was going to use for the lower baffles is of lesser quality and has voids which is troublesome because all you were going to see were the plies once the acacia was glued on. I have some half inch birch plywood that would work, but just remember that I will now have some scrap rift & quarter sawn white oak flooring I could use. This will be the flooring that the speakers are sitting on in the new house. Suggestions?

I'd go with the 2nd pic - Acacia

I'd buy more baltic birch personally, but that's probably just me. I have issues.....carry on.

Removable baffles without stiffening on the back of them will tend to flex at 3/4" thicknesses. I recommend 2 more bolts in the middle to keep them firmly mounted w/o flex.

InDIYana Event Website

Thanks for the feedback. I have a plan to use 3/4 birch scraps to fill the need and achieve the aesthetic. Ben, I'll look into adding another pair of bolts while maintaining symmetry.

You are welcome! My Fenrir had 1.25" thick MDF baffles, and I should have used 2 more bolts for best flatness. Therefore, I did on the Versabox related builds, and all have 6 mounting bolts.

InDIYana Event Website

I was away for a bit, but was able to add the extra mounts for the baffles so that each will be held on with 6 bolts.

Those look sturdy. Looking good🤘🏼

Here is my solution utilizing scrap baltic birch. I will be gluing on a piece of the acacia butcher block over this.

One lower baffle flush trimmed and ready to glue to the plywood.

Now onto final sanding and shellacking the inside.

Why the step? You can screw the acacia directly instead of the ply backer

Good question Ani. Since the woofer and tweeter are no longer obtainable and I have a four and a half year old, grills are a must. I didn't show the grill in my cad files, but I plan on CNCing a grill with magnets where the bolts are. The magnets may not be strong enough to hold the grill up, but should hold it against the baffle and the step will hold it up. The grill will be flush with the lower acacia baffle and hopefully provide a clean aesthetic. Another reason for the ply backer is to prevent the acacia from splitting when tightened down.

Thanks, must have missed the note about the grill. looks good... looking forward to the finish

Grills cut from 5/8 value shelf

I would line that inner grille edge with felt.

InDIYana Event Website

I might chamfer the inner edge but will usually remove the grills for listening. The speaker wire arrived...